Product List

Hot News

Contact Us

E-mail:sales2@eejaxt sales3@eejaxt.com sales4@eejaxt.com Add: No. 5-6 of East Road 2, Lianhe Industry Zone of Luo Cun, Shishan Town of Nanhai District Foshan City, China

Wire Drawing Machinery

Current Location:Home > Product > Wire Drawing Machinery >- Spec

- Scope

- Dimensions

- Product Description

LB 8多功能联合连续拉拔机组的主要技术性能和技术规范如下:

1. Processed materials: ferrous and non-ferrous metals like steel, copper alloy and Aluminum alloy;

2. The rated pulling force:80 KN(8 tons)

3. Wire running speed:20、30、40、50、60 m/min

4. Max wire coil weight:1000 kg

5. Finished bar size:round bar ∅8~∅20 mm,square bar 18 x 18 mm,hexagon bar 20 x 20 mm

6. Finished bar length:2~6 m

7. Finished bar straightness:<5 mm/m

8. Finished bar finish roughness:Ra 1.6~0.8 um

9. Key motor power:110 KW

10. Total power of the whole line:188 KW

11. Number of phases:3

12. Power frequency:50 Hz

13. Power voltage:380 V

14. Total weight of the whole line:26 Tons

15. Max covered area(Excluding electrical control cabinet):around 32000*3000*1320 mm

16. Environmental temperature:0°C~40°C

17. Environmental humidity:

a) 50% RH when the temperature is <35°C

b) 90% RH when the temperature is<20°C

18. Environmental medium requirement:no explosive materials, no corrosive material and no harmful gas and dust for electrical insulation of electrical wires

19. Altitude that it can run under:≤1000 m

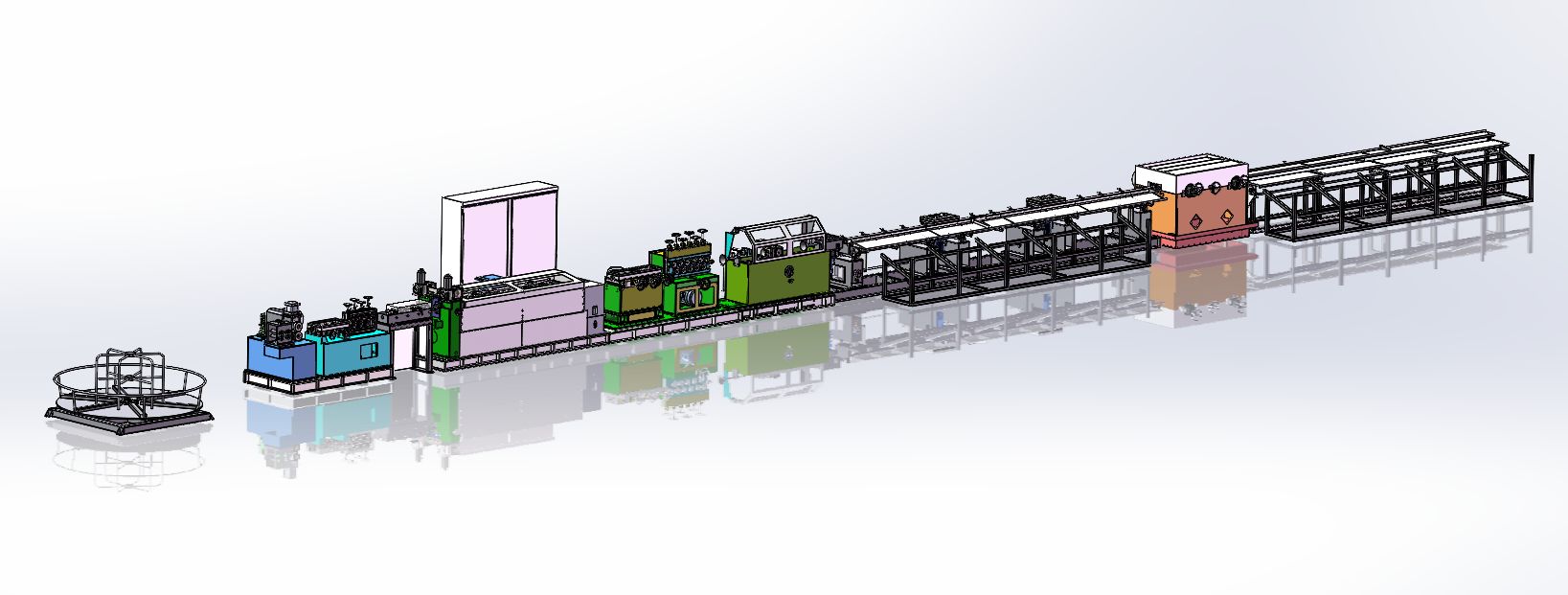

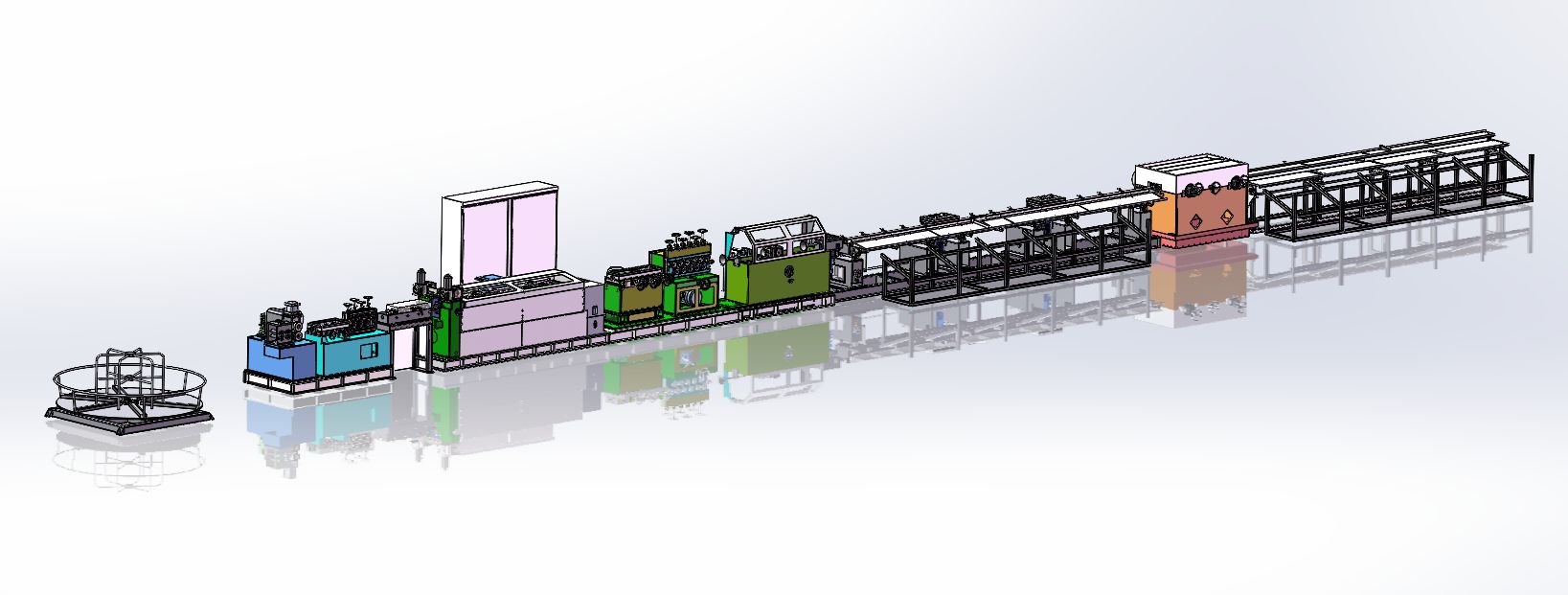

Our LB8 is a non-stop running wire drawing machinery production line combined of multi processes and functions. It can produce straight metal wire with different wire section shape like round and square, different wire section dimension (diameter) and different length.

It is combined of wire coil decoiling, pre and final straightening. length measuring and cutting, polishing and finished straight wire collection. It covers less space and can run continuously with high efficiency.

It can process ferrous and non ferrous metal like steel wire, copper alloy wire and Aluminum alloy wire.

The metal wire profiles, produced on the wire drawing machine, have the characteristics of accurate dimensions, correct section shape and precisive finish as well as improved mechanical properties. The suitable size can help reduce the machining amount in turning and milling processes on lathes and CNC. The process of cold-drawing through a die consumes less power than other size reduction way of a metal wire. And it can produce high quality size (diameter) wire with high efficiency and lower power consumption.

Next: NO